The human eye is an absolutely remarkable part of the body and allows us to take in an astonishing amount of critical information about our surroundings and environment. Our eyes give us the wonderful gift of a rich and vivid experience within our world; this evokes emotion, provides daily function and key elements for survival. But you only get one set of eyes! Which brings a major concern to the forefront of our minds, “What are the best ways to protect our eyes?” One of the most important aspects of eye protection is shielding us from hazardous highspeed objects, hurling towards our face. When it comes to eyewear, there is a vast range of impact resistance performance levels and it’s important to understand what those levels are and the level of threats that can be mitigated.

Impact performance is the measurement of a safety eyewear system’s ability to disperse kinetic energy when hit by a projectile. This is similar to terminal ballistics analysis. When a projectile hits a safety eyewear system, the kinetic energy is transferred to the lens or other eyewear components. We study this transfer of energy to create eyewear that can withstand most projectiles.

Using advanced materials such as engineering polymers and high-performance alloys is vital to the performance of impact resistant eyewear. The mechanical properties and behaviors of these materials, such as high molecular weight polycarbonate and nickel-titanium, provide the necessary structure to hold the eyewear comfortably in place and absorb impact energy at the same time.

The design and geometry of eye protection should accomplish a few goals. Well designed eye protection allows the lens and frame to dissipate impact energy in a safe manner for the wearer. It is important that impact energy is distributed and diverted through the lens and frame without concentration near the eyes. We design our eye protection systems to stay on the head of the wearer while maintaining integrity. This includes the individual components such as lens/lenses, frame components, nose pieces, etc…

Standards

US Military impact standards are by far the most stringent for commonly available eye protection.

- Spectacles .15 Caliber (6gr) T37 Fragment Simulator @ 650fps

- Goggles .22 Caliber (17gr) T37 Fragment Simulator @ 550fps

- US Military standards also require compliance with ANSI Z87.1+

ANSI Z87.1+

- Spectacles .25 Caliber Ball Bearing @ 150fps

- 500 gram High Mass Impact (Falling Dart)

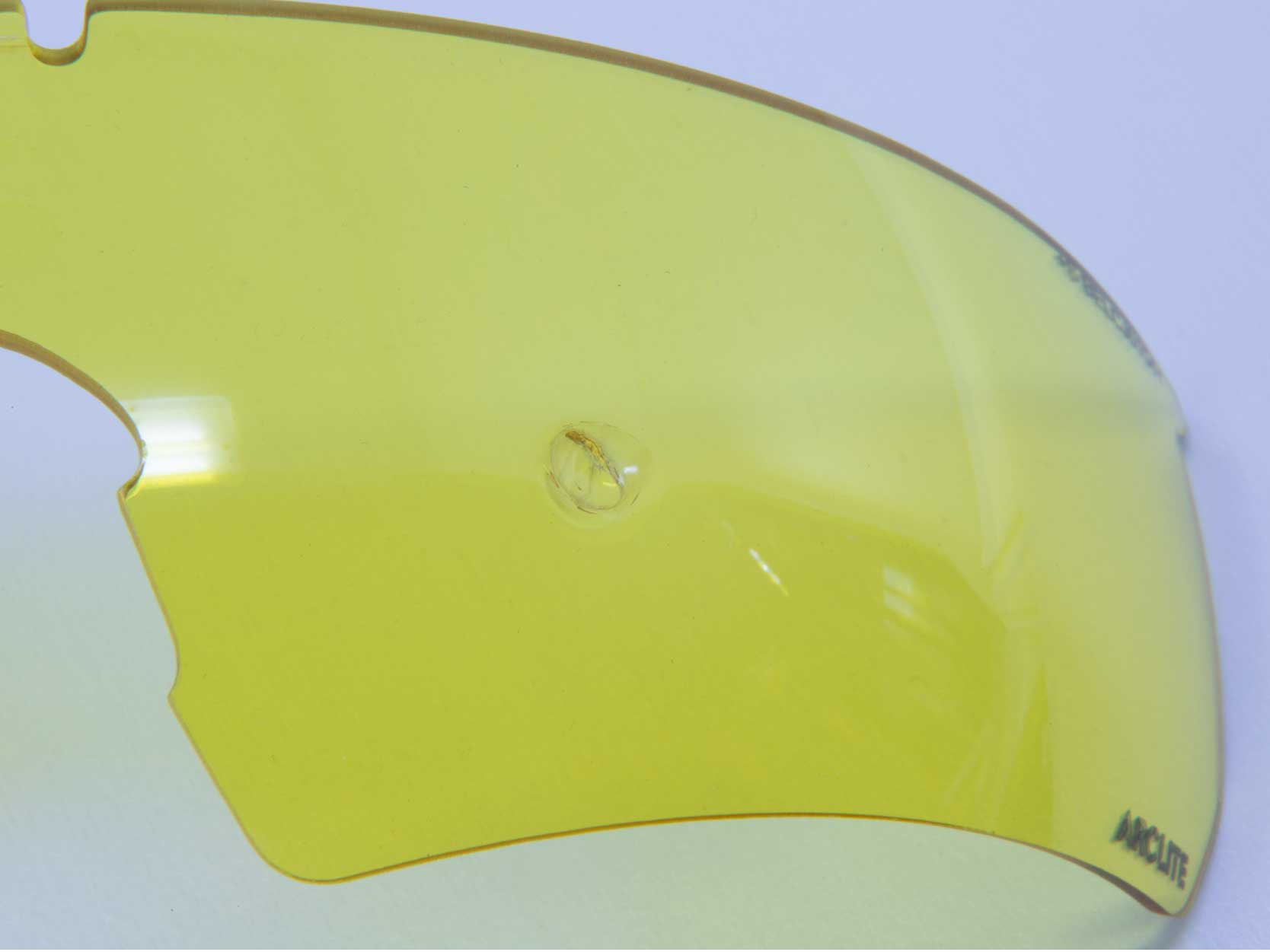

The difference in the severity of impact is massive between military standards and ANSI Z87.1. A typical pair of safety glasses will show very little or no damage after a 150fps strike with a ball bearing. Whereas an impact of a t37 fragment simulator at 550-650 fps will leave a noticeable divot in the lens in the best-case scenario and a complete failure by fracture in the worst-case scenario.

Testing

When testing eye protection, it is critical that testing be done on an ongoing basis. The sample rate must also be sufficiently large to detect failures. It is common for failure rates of defective military eye protection products or defective manufacturing lots to be in the 1-3% range under laboratory testing. So, companies who are truly compliant with military ballistic standards will shoot thousands of lenses regularly to detect problems. It’s simply not enough to shoot a few lenses and assume everything is good to go. You don’t want to be one of the 3 people out of 10 wearing product that doesn’t meet the standards. So, selecting companies that conduct ongoing continuous testing, and not just occasional 3rd party testing, is paramount.

V50 vs V0 Testing

- There are 2 modes of failure that account for almost all breaks of protective lenses. V50 testing is used to determine the projectile velocity at which a 50% statistical failure rate occurs.

- V0 testing is conducted to determine the projectile velocity at which a 0% statistical failure rate occurs. Generally, a break of the inner concave surface of the lens or a break of a witness foil placed over the eyes of the test head form is a failure.

- In the case of both V50 testing and V0 testing, a large enough sample size must be used to obtain significant data. For military grade protective lenses, V50 testing is generally used to determine the lenses resistance to the projectile piercing the lens with a ductile failure. Whereas V0 is more commonly used to detect a quality problem or nonconformance with production lenses.

- For any given polymer material used for impact resistant eyewear lenses, the behavior varies substantially depending on the speed at which the material reacts from an impact event. Strain rate is one of the terms used to describe the rate of reaction (deformation) of the lens material from the impact of a projectile. These polymers behave in a more brittle manner as impact velocity and thus strain rate increases. This is why high velocity impact testing to military standards is important. This is also why the use of high molecular weight polymers which behave in a ductile manner at higher strain rates is important. A product that could be impacted repeatedly without fracture at lower strain rates, by a swinging golf club for example, might fail catastrophically when impacted with a T37 fragment simulator at military testing velocities.

Processing-Compounding heat history

Using the right materials for protective eyewear is essential for good impact performance. Many of the leading manufacturers use high quality materials which are similar to or the same as used by other companies. Using the right materials isn’t enough for good impact performance. The way these materials are processed in the manufacture of protective eyewear is equally important.

Molding

High molecular weight impact resistant optical polycarbonate resins are used in molding the substrate of lenses for all military grade protective eyewear. However, processing these materials presents some technical challenges that require manufacturing capabilities and knowledge that is unique. Only a handful of lens manufacturers in the world can do it well on a consistent basis.

Higher molecular weight optical resins are more viscous and have higher melt flow rates. So minimizing the heat history and shear throughout the compounding and molding processes is critical to maintain the integrity and performance of the material. This is why choosing a manufacturer that has the right machines, molds and the know how to use them properly is essential to ensuring good consistent impact performance.

Coating

The molding and compounding process are important. However, the lens coating processes are more important for ballistic performance and more difficult to do well. Functional coatings are necessary, because they provide scratch resistance, chemical resistance and anti-fog. However, these coatings can also embrittle the lens due to the composite effect on the lens as a system. Selecting the right coating materials is critical.

The affect coatings have on the ballistic performance of protective lenses can be dramatic. Seemingly imperceptible coating process variations can cause lenses to fracture on impact. There is a balance between the performance of the coatings and the ballistic performance of the lens as a whole system. This balance becomes more difficult to achieve as the number of coatings on the inside and outside of the lens increases. Developing coating processes, equipment and knowledge which are adequate for ballistic lens performance takes many years of dedicated work.